HB Linear Actuator Overview

Release Time:

2023-07-19

Overview of HB Linear Actuators

CONTENT

1. Working Frequency / Duty Cycle

6. Installation Size & Mounting Ends

▼ 1. Working Frequency / Duty Cycle [Go Top]

When selecting a product, most people's first consideration is likely the 'load' requirement. However, when faced with numerous brands and models of products, the usage frequency has divided the electric actuators on the market into two main factions.

- High frequency - electric cylinder

- Low frequency - electric linear actuator

Different operating frequencies determine the motor type and transmission method. For example, in high-frequency applications, servo motors, stepper motors, and brushless motors are commonly used. These motors often work with high-efficiency ball screws, which are suitable for continuous and high-speed operation over long hours. On the other hand, low-frequency applications typically utilize cost-effective brushed DC motors, working with ACME screws or ball screws, offering a good balance between performance and affordability. If your application does not require high-frequency operation, you can choose a brushed DC motor. There are primarily four options:

12v、24v、36v and 48v DC

There is no such thing as one being better or worse between these two types of motors. They are simply born for different application scenarios.

How do you determine whether your usage condition is high-frequency or low-frequency? Unfortunately, there isn't a very clear definition within the industry. Various factors such as product design, manufacturing processes, quality of raw materials, assembly techniques, and the specific parameters and usage conditions can all contribute to different lifespans for the overall system.

Let's assume the product's maximum experimental lifespan is 100,000 cycles (one complete back-and-forth motion equals one cycle), and your usage frequency is 100 cycles per day. Theoretically, you can use it for 1,000 days (approximately 3 years). Therefore, you only need to assess whether you can accept replacing the actuator every three years.

However, as mentioned earlier, there are many factors that can affect the product's lifespan. It would be best to provide us with detailed information about your projected parameters and usage conditions so that we can make a comprehensive evaluation.

|

Model |

Duty Cycle [%] |

Max Rated Dynamic Force |

Motor |

Voltage |

Leadscrew |

|

100 |

20,000 |

3-phase AC |

220 |

Ball |

|

| HB-DJ812 |

100 |

20,000 |

Servo AC |

380 |

Ball |

|

100 |

8,400 |

Servo AC |

380 |

Ball |

|

| HB-DJ815 |

100 |

7,000 |

3-phase AC |

220 |

Ball |

|

100 |

4,500 |

Servo AC |

380 |

Ball |

|

| HB-DJ819 |

100 |

3,700 |

3-phase AC |

220 |

Ball |

|

50 |

20,000 |

Brushed DC |

48 |

Ball |

|

|

50 |

8,000 |

Brushed DC |

48 |

Ball |

|

|

50 |

4,000 |

Brushed DC |

48 |

Ball |

|

|

25 |

7,000/10,000 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

25 |

12,000 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

25 |

7,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

25 |

4,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

25 |

2,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

25 |

1,200 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

20 |

2500/1000 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

20 |

20,000 |

Brushless DC |

24, 48 |

Ball |

|

|

20 |

15,000 |

Brushed DC |

24, 48 |

Ball |

|

|

20 |

8,400 |

Brushless DC |

24, 48 |

Ball |

|

|

20 |

4,000 |

Brushless DC |

24, 48 |

Ball |

|

|

20 |

2,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

10 |

6,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

10 |

6,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

10 |

4,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

10 |

2,000 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

10 |

1,500 |

Brushed DC |

12, 24 |

ACME |

▼ 2. Voltage & Motor [Go Top]

Keywords: linear actuator 12v, linear actuator 24v,

24vdc linear actuator, 12v dc linear actuator,

high speed linear actuator 12v, heavy duty linear actuator 12v,

linear actuator 12v 1000lbs, fast linear actuator,

24 volt actuators, electric linear actuator 12v,

HB-DJ series linear actuators can be equipped with 12V, 24V, 36V, or 48V DC brushed motors. There are also several models available that support AC, servo, and brushless motors. Please refer to the table below for more details.

|

model |

Motor |

Voltage |

Duty Cycle |

Max Rated Dynamic Force |

|

Brushed DC |

24, 48 |

20 |

15,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

7,000/10,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

20 |

2500/1000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

12,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

7,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

10 |

6,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

10 |

6,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

4,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

10 |

4,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

2,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

20 |

2,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

10 |

2,000 |

|

|

Brushed DC |

12, 24, 36, 48 |

25 |

1,200 |

|

|

Brushed DC |

12, 24 |

10 |

1,500 |

|

|

Brushed DC |

48 |

50 |

20,000 |

|

|

Brushed DC |

48 |

50 |

8,000 |

|

|

Brushed DC |

48 |

50 |

4,000 |

|

|

Brushless DC |

24, 48 |

20 |

20,000 |

|

|

Brushless DC |

24, 48 |

20 |

8,400 |

|

|

Brushless DC |

24, 48 |

20 |

4,000 |

|

|

3-phase AC |

220 |

100 |

20,000 |

|

|

3-phase AC |

220 |

100 |

7,000 |

|

|

3-phase AC |

220 |

100 |

3,700 |

|

|

Servo AC |

380 |

100 |

20,000 |

|

|

Servo AC |

380 |

100 |

8,400 |

|

|

Servo AC |

380 |

100 |

4,500 |

▼ 3. Stroke Length [Go Top]

In theory, the length of an electric linear actuator can be customized according to specific requirements. However, in order to ensure product safety, we impose certain constraints on the customizable stroke range, typically within 1000mm. If your required stroke exceeds this customization range, we will conduct a comprehensive feasibility analysis based on the actual operating conditions of your equipment. You are welcome to contact us at +86-0510-81011388 or email us at media@wxhongba.com for further assistance.

▼ 4. Load & Speed [Go Top]

Keywords: high force linear actuator, heavy duty electric linear actuator,

high speed linear actuator, heavy duty linear actuator,

6000n linear actuator,

The rated operating speed of the product is generally inversely proportional to the rated load you choose. In other words, the larger the load, the slower the speed. If you do not have specific speed requirements, it is recommended to prioritize choosing a slower gearset. This will provide a higher load margin, safety factor, and longer product lifespan.

In our standard product series, we offer models that can support a maximum rated load up to 2 tons. We also have smaller and lightweight linear actuators available in various sizes.

|

model |

Max Rated Dynamic Force |

Max Speed |

Duty Cycle |

Motor |

Voltage |

Leadscrew |

|

20,000 |

83 |

100 |

3-phase AC |

220 |

Ball |

|

|

20,000 |

83 |

50 |

Brushed DC |

48 |

Ball |

|

|

20,000 |

80 |

20 |

Brushless DC |

24, 48 |

Ball |

|

|

20,000 |

60 |

100 |

Servo AC |

380 |

Ball |

|

|

15,000 |

11 |

20 |

Brushed DC |

24, 48 |

Ball |

|

|

12,000 |

37 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

7,000/10,000 |

35 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

8,400 |

75 |

100 |

Servo AC |

380 |

Ball |

|

|

8,400 |

60 |

20 |

Brushless DC |

24, 48 |

Ball |

|

|

8,000 |

60 |

50 |

Brushed DC |

48 |

Ball |

|

|

7,000 |

57 |

100 |

3-phase AC |

220 |

Ball |

|

|

7,000 |

35 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

6,000 |

28 |

10 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

6,000 |

16 |

10 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

4,500 |

70 |

100 |

Servo AC |

380 |

Ball |

|

|

4,000 |

57 |

50 |

Brushed DC |

48 |

Ball |

|

|

4,000 |

57 |

20 |

Brushless DC |

24, 48 |

Ball |

|

|

4,000 |

35 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

4,000 |

32 |

10 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

3,700 |

54 |

100 |

3-phase AC |

220 |

Ball |

|

|

2,000 |

55 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

2,500/1,000 |

22 |

20 |

Brushed DC |

12, 24, 36, 48 |

ACME/ Ball |

|

|

2,000 |

19 |

10 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

2,000 |

15 |

20 |

Brushed DC |

12, 24, 36, 48 |

ACME |

|

|

1,500 |

32 |

10 |

Brushed DC |

12, 24 |

ACME |

|

|

1,200 |

80 |

25 |

Brushed DC |

12, 24, 36, 48 |

ACME |

▼ 5. Working Environment [Go Top]

Keywords: waterproof linear actuator, linear actuator 12v waterproof,

There are two main dimensions to consider for environmental conditions: IP rating and working temperature.

|

model |

IP Rating |

Working Temp. |

Duty Cycle |

Max Rated Dynamic Force |

|

66 |

-40 to 65 |

25 |

12,000 |

|

|

66 |

10 to 65/ -40 to 65 |

25 |

2,000 |

|

|

66 |

10 to 65/ -40 to 65 |

25 |

1,200 |

|

|

66 |

10 to 65/ -40 to 65 |

20 |

2,500/1,000 |

|

|

66 |

10 to 65/ -40 to 65 |

20 |

2,000 |

|

|

65 |

-15 to 40 |

20 |

15,000 |

|

|

65 |

10 to 65/ -40 to 65 |

25 |

7,000/10,000 |

|

|

65 |

10 to 65/ -40 to 65 |

25 |

7,000 |

|

|

65 |

10 to 65/ -40 to 65 |

25 |

4,000 |

|

|

55 |

-15 to 40 |

100 |

20,000 |

|

|

55 |

-15 to 40 |

100 |

20,000 |

|

|

55 |

-15 to 40 |

100 |

8,400 |

|

|

55 |

-15 to 40 |

100 |

7,000 |

|

|

55 |

-15 to 40 |

100 |

4,500 |

|

|

55 |

-15 to 40 |

100 |

3,700 |

|

|

55 |

-15 to 40 |

50 |

20,000 |

|

|

55 |

-15 to 40 |

50 |

8,000 |

|

|

55 |

-15 to 40 |

20 |

20,000 |

|

|

55 |

-15 to 40 |

20 |

8,400 |

|

|

55 |

-15 to 40 |

20 |

4,000 |

|

|

55 |

10 to 65/ -40 to 65 |

50 |

4,000 |

|

|

54 |

-15 to 40 |

10 |

6,000 |

|

|

54 |

-15 to 40 |

10 |

2,000 |

|

|

43 |

5 to 40 |

10 |

6,000 |

|

|

43 |

5 to 40 |

10 |

4,000 |

|

|

20 |

5 to 40 |

10 |

1,500 |

[Portal] Definition of IP rating.

In addition to that, in specific application scenarios, linear actuators may need to withstand harsh environments such as vibration, impact, chemical corrosion, and overvoltage. Therefore, please provide detailed information about the actual working environment of your equipment so that we can take sufficient protective measures for the product and extend its overall lifespan.

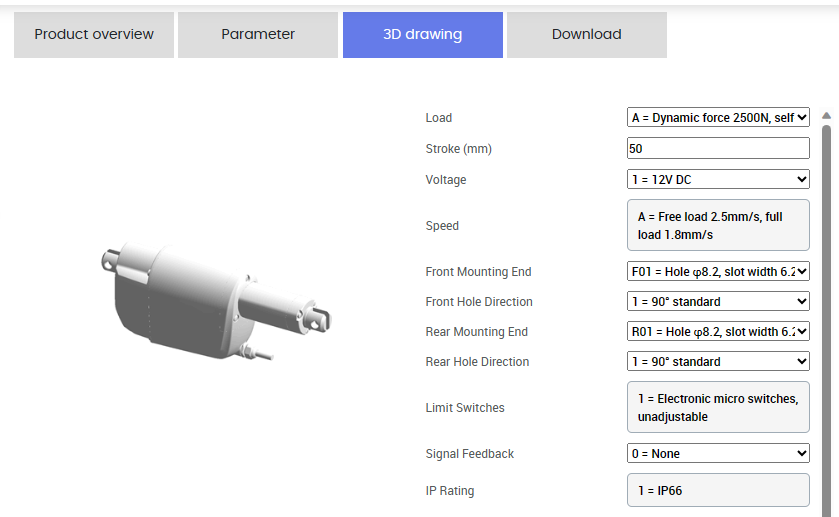

▼ 6. Installation Size and Mounting Ends [Go Top]

The installation dimensions of a linear actuator are not only dependent on the baseline profile dimensions of the product itself but also on the style of mounting ends chosen for both sides. To assist you in quickly determining the dimensional compatibility of the product, we have launched a self-service 3D drawing generation system specifically for our engineering customers. With just a few clicks of the mouse, you can export various formats of 3D and 2D drawings.

▼ 7. Position Feedback [Go Top]

Keywords: linear actuator with position feedback, linear actuator with feedback,

linear actuator with potentiometer, linear actuator position control,

Our HB-DJ series electric linear actuators can be equipped with four types of position feedback sensors: Hall sensor, endstop signal, potentiometer, and magnetic reed switch.

|

Positon Feedback |

|||||

|

Model No. |

Hall Effect |

Endstop Signal |

Potentiometer |

Reed Switch |

Max Dynamic |

|

Y |

Y |

Y |

Y |

2,000 |

|

|

Y |

Y |

Y |

7,000/10,000 |

||

|

Y |

Y |

Y |

12,000 |

||

|

Y |

Y |

Y |

7,000 |

||

|

Y |

Y |

Y |

4,000 |

||

|

Y |

Y |

Y |

2,000 |

||

|

Y |

Y |

2500/1000 |

|||

|

Y |

6,000 |

||||

|

Y |

6,000 |

||||

|

Y |

4,000 |

||||

|

Y |

2,000 |

||||

|

Y |

Y |

Y |

1,200 |

||

|

20,000 |

|||||

|

20,000 |

|||||

|

20,000 |

|||||

|

20,000 |

|||||

|

15,000 |

|||||

|

8,400 |

|||||

|

8,400 |

|||||

|

8,000 |

|||||

|

7,000 |

|||||

|

4,500 |

|||||

|

4,000 |

|||||

|

4,000 |

|||||

|

3,700 |

|||||

|

1,500 |

|||||

Keywords:

Related Announcements